Home »

Our Products » Laboratory Instruments

Coal Testing Instruments

Hardgrove Grindabllity Apparatus

The Grindability Of Coal is a measure of the ease

with which it can be ground fine enough for use as a pulverised fuel, &

it also shows the physical properties of coal like hardness, tenacity and

fracture. There is a fixed relationship between Grindability and rank of

coal in the natural series from brown coal to lignite & anthracite.

Coals easier to grind have 14 to 30 percent volatile matter Coals with

higher volume matter are more difficult to grind. However petrographic &

mineral constituents influence grindability. The hardgroove index of coal is

affected by its moisture content and hence on the humidity of the atmosphere

in which the test is carried out.

Experimental Procedure

1 kg of coal sample was taken and crushed to pass

through 4.73mm sieve. The resulting sample was put in two steve of 1.18mm

sieve (upper sieve) and +600 size(kwer sieve). Sieve the materiol for 2

minutes until the entire material pass through 1.18mm sieve* The 1.18mm by

600 size coal was mixed thoroughly and 120 gm of the sample was removed for

sample divider The 30gm sample was taken in a ball mill along with 8 iron

baits with diameter 234*0 003 mm. The mouth of the ball mill was closed and

it was set to rotate for about 60 revolutions, when the rotation is

achieved, the machine was stopped. The sample left in the ball mill was then

collected along with any powdered substance sticking to the surface of the

machine by help of a brush* This sample was then put in a sieve of 73 size

and was shaken for about 10 minutes. After sieving for about 3 minutes, the

sample which passes through 73 size was weighed on the balance.

Calculation - The hard groove grindobility index of coal is calculated using

the following formula. HGI = 13 + 6.93 W. W = weight of the test sample

passing through 73 sieve after grinding

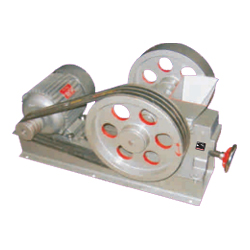

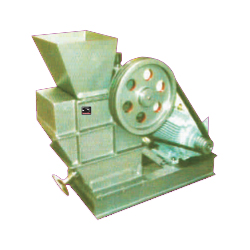

Jaw Crusher

Laboratory Crusher is designed to speed up the

crushing of aggregate, ores, minerals. Coal, Coke, Chemicals and other

similar materials. It is compact and of rugged construction for general

laboratory or small pilot plant operations.

Two taws of manganese steel ore provided in the jaw crusher The moveable jaw

produces two blows for every revolution thus reducing over sizing to a

minimum. A combination of forward and downward and strokes with a rooking

action exerts pressure on the coarse material yet permits the finished

material to pass through the taws. A hopper is provided at tfw top for

feeding materials. The smooth jaws ensure a uniform product and easy

cleaning is possible. The out put size can be adjusted by the lock nut

provided to adjust the jaws.

| Code |

Jaw Size |

Feed Size |

Output Size |

Power 440 Volts |

| SHJ-600A |

4 x 10" |

25-30mm |

6-20mm |

3HP |

| SHJ-600B |

6 x 12" |

45-50mm |

10-22mm |

5HP |

| SHJ-600C |

8 x 16" |

65-70mm |

12-25mm |

10HP |

| SHJ-600D |

12 x 20" |

90-100mm |

20-30mm |

10HP |

| SHJ-600E |

15 x 24" |

100-150mm |

25-30mm |

15HP |